Casting takes a material that is in a flowing or liquid state and puts that material into a container or Mold that restricts its flow until it stops flowing. The method for stopping the flow can be either temperature or chemical based.

For example, in slip casting of clay, when the clay dries it no longer flows and can be removed from the mold.

Types of Casting

Metal Casting

Various metals can be cast into molds using a variety of processes. Common metals used in casting include iron, bronze, aluminum, and stainless steel. The size of metal casting can range from large statues or pieces of machinery, to small, delicate cast pieces of jewelry.

Bronze Casting

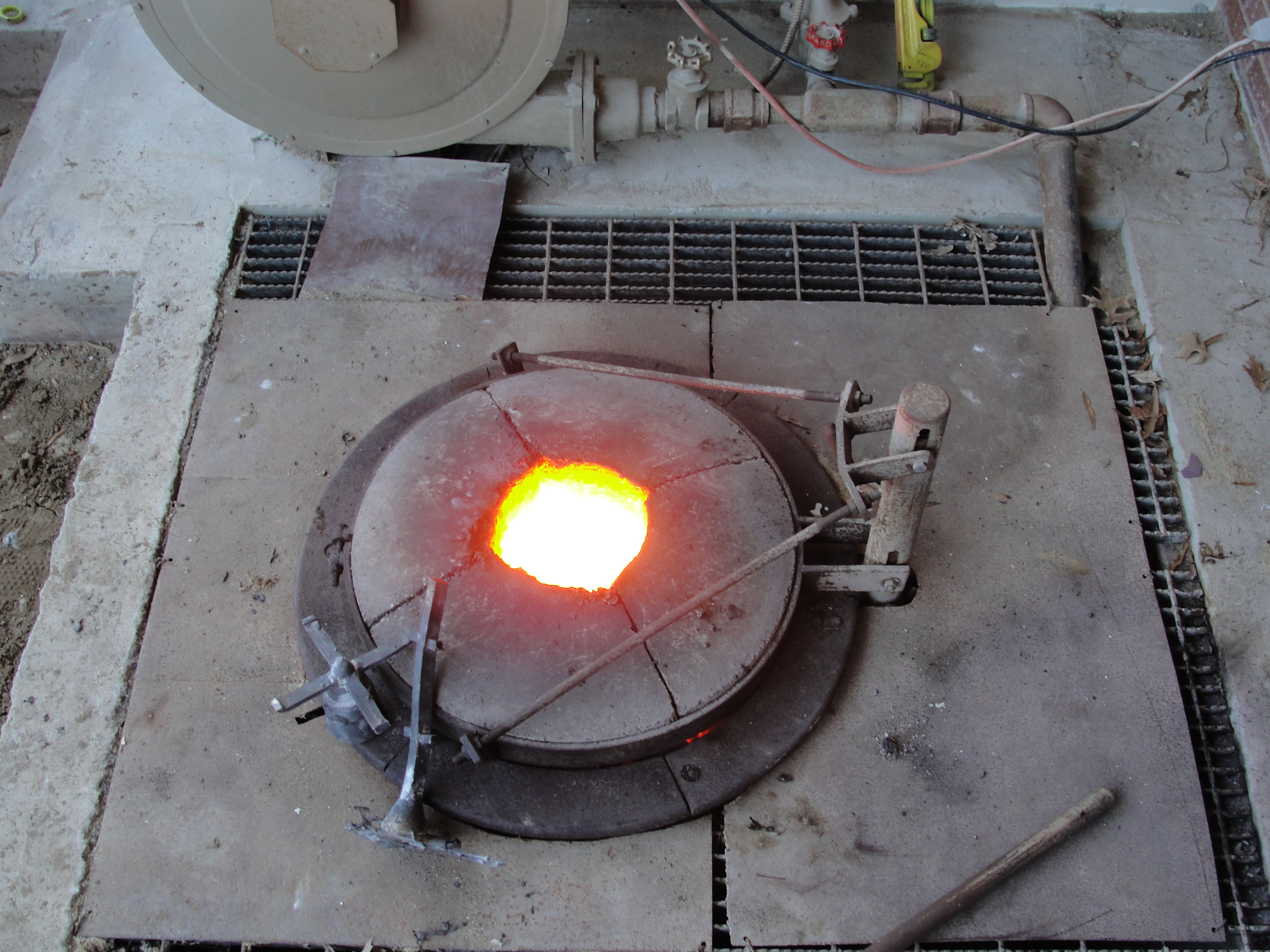

Bronze-Casting is a common form of metal casting because of its lower melting point than iron. Bronze is melted in a crucible in a blast furnace as shown in the image below.

Iron Casting

Iron Casting requires much hirer heat than bronze or aluminum casting.

Plaster Casting

Plaster casting is a reliable method of making a positive cast of a form. Plaster is also often used as a mold making material.

Materials Used in Casting

Ceramic Shell

Investment

Crucible

Tongs